Last year, AST Grupo rehabilitated a total of 2,347 meters of a sewage pipe with Berolina-HF-Liners in Asturias, Spain. So far so normal. The fact that the box profiles of the discharge pipe sewers, which primarily measure 1,400 x 1,000 mm, have different dry weather gutters, a number of step joints and crossing lines in the crown area made it an ambitious undertaking. But thanks to tireless the commitment and meticulous preparation, AST mastered the renovation in two project phases with the support of BKP Berolina GmbH & Co. KG and JBP Composites S.L brilliantly.

AST Grupo had to plan one of the largest liner rehabilitation measures ever carried out in northern Spain precisely. Thorough cleaning work enabled inspection of the sewers reaches to determine which liner design would be most appropriate for the project and what the requirements for the liners to be installed should be. When selecting the product, AST Grupo opted for BKP’s Berolina-HF-Liner due to its high mechanical properties, special extension behaviour and low cross-section loss. The flexible design of the liner enabled rehabilitation to be carried out in line with the special profile and the fulfillment of all the requirements that the project entailed.

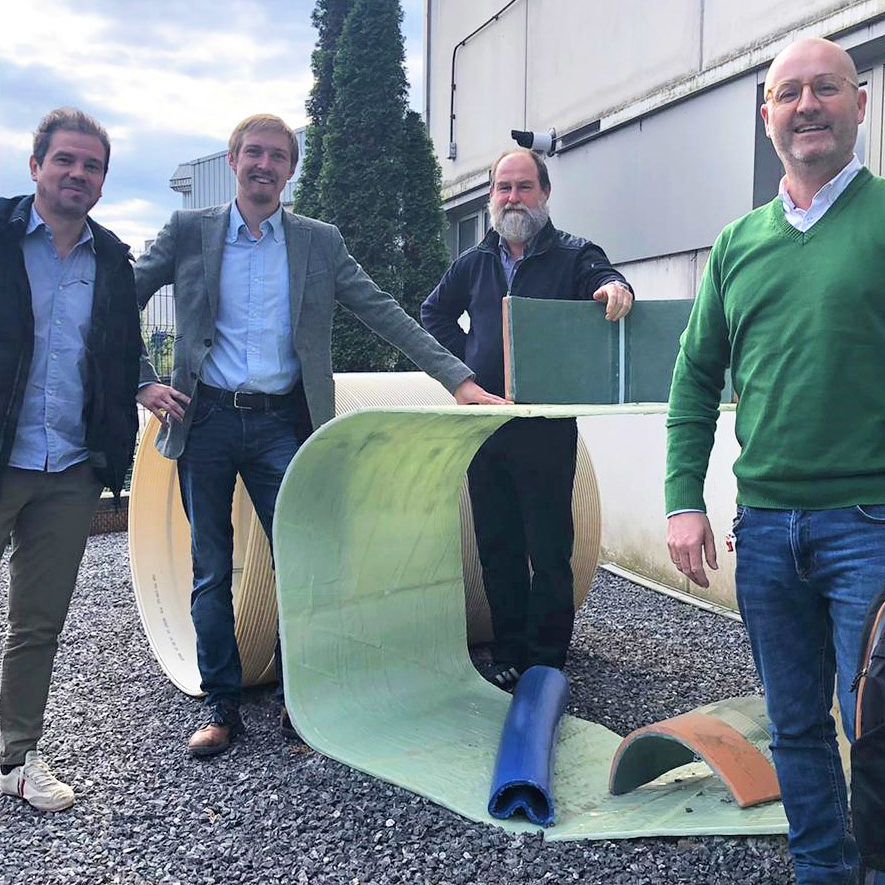

The teams from all three companies involved in the rehabilitation then met to review the inspection data and determine the most appropriate liner for each pipe. After the consultation, custom-made liners were produced in the BKP factory in Velten near Berlin and delivered directly to the construction site in Asturias.

After thorough preparation of the job site, the installation of the liners could start. A 6-tonne winch was used to pull the hoses into the host pipes to be renovated on site. The liner ends were sealed with end-cans and the curing process after the UV light sources had been introduced could begin. Particular attention was paid to the special profile when setting up the liner. They were carefully and incrementally calibrated with compressed air to ensure that the fiberglass layers could slide past each other during the inflation process. The Berolina-HF-Liners are ideally adapted to the special profile of the pipes to be renovated, leading to a result in this case that delivered excellent performance in the pipe, was more than just its visual appearance.

In order to ensure complete curing of the liner, BKP provided specific advice. Compliance with the mechanical and static values clearly declared in advance was of overriding importance. The host pipes were finally lined and sealed from the inside and the structural resilience was restored. A maximum wall thickness of ten millimeters was sufficient to permanently strengthen the old pipes.

The follow-up inspections proved that the new inner pipes were properly installed without any abnormalities. Thanks to careful planning and an excellent team of installers and technicians, the project was successfully completed.

With the successful completion of each new project such as this one, the use of UV Cured CIPP rehabilitation methods, and more generally trenchless technologies, further proves to network operators the efficiency, cost-effectiveness, and reliability of these solutions, not to mention the environment benefits. And this at a time when there is increasing pressure and focus on maintaining infrastructure intelligently.

AST Grupo – contractor

The family business AST Grupo from Langreo in Asturias offers efficient and cost-effective trenchless rehabilitation of pipes using different technologies and methods. AST has its own equipment to be able to carry out the necessary work independently throughout Spain. The company has been installing glass fiber reinforced liners for many years.

BKP Berolina – product manufacturer and support

The company from Velten near Berlin was the supplier for this project. As a globally recognized supplier and manufacturer of UV light-curing hose liners for pipeline rehabilitation, BKP is represented in more than 40 countries. The Berolina-Liner System offered an optimal, efficient and cost-effective solution for the renovation work in northern Spain. By using the Berolina-HF-Liner, time-consuming excavation work was avoided and the environmental impact was minimized. During the execution of the project, BKP provided technical support for AST, conducted training and provided installation equipment.

JBP Composites – support and technology provider

With its local presence in Valencia, Spain, and more than 35 years of international experience working with trenchless technologies, JBP was able to support the companies AST and BKP in the project.