Other sizes on request.

Berolina-LP-Liner: Area of application

Pressure pipes up to 3 bar operating pressure

- Circular profiles: ID 150 (6“) – ID 600 (24“)

Berolina-LP-Liner: Advantages

- Use in low-pressure range

- Seamless design

- Ready for installations up to 500 metres

- Can be stored for at least 5 months

- Fast curing

- Smooth surface

- Suitable for all standard pipe profiles

- Bridging small profile and cross-section changes

Reinforcement material

Woven glass complex E-CR according to EN 14020-1, EN 14020-2 and EN 14020-3

Resins

Unsaturated polyester resins (UP resins)

- Type 1140 according to DIN 16946-2

- Group 3 according to DIN 18820-1

- Group 4 according to EN 13121-1

Technical data

Short-term ring stiffness (EN 1228)*: ≥ 10,000 N/mm²

Short-term modulus of elasticity in flexure (EN ISO 178)*: ≥ 8,700 N/mm²

Short-term flexural strength (EN ISO 178)*: ≥ 150 N/mm²

Reduction factor for long-term values (EN 761): A = 1.45

Long-term ring stiffness (EN 1228)*: ≥ 6,800 N/mm²

Long-term flexural strength (EN ISO 178)*: ≥ 105 N/mm²

Laminate design: Multi-layer, seamless and overlapping in longitudinal direction; overlaps are offset

Linear expansion during calibration: ~ 0.0%

Allowable diameter tolerance of the host pipes: DN ≤ 600: ± 5%

* Carrier laminate thickness to EN ISO 11296-4 (07/2011)

Data sheet

Brochure

Further language versions will follow.

-

- Area of application

-

Berolina-LP-Liner: Area of application

Pressure pipes up to 3 bar operating pressure

- Circular profiles: ID 150 (6“) – ID 600 (24“)

Other sizes on request.

- Advantages

-

Berolina-LP-Liner: Advantages

- Use in low-pressure range

- Seamless design

- Ready for installations up to 500 metres

- Can be stored for at least 5 months

- Fast curing

- Smooth surface

- Suitable for all standard pipe profiles

- Bridging small profile and cross-section changes

- Technical data

-

Reinforcement material

Woven glass complex E-CR according to EN 14020-1, EN 14020-2 and EN 14020-3

Resins

Unsaturated polyester resins (UP resins)

- Type 1140 according to DIN 16946-2

- Group 3 according to DIN 18820-1

- Group 4 according to EN 13121-1

Technical data

Short-term ring stiffness (EN 1228)*: ≥ 10,000 N/mm²

Short-term modulus of elasticity in flexure (EN ISO 178)*: ≥ 8,700 N/mm²

Short-term flexural strength (EN ISO 178)*: ≥ 150 N/mm²Reduction factor for long-term values (EN 761): A = 1.45

Long-term ring stiffness (EN 1228)*: ≥ 6,800 N/mm²

Long-term flexural strength (EN ISO 178)*: ≥ 105 N/mm²Laminate design: Multi-layer, seamless and overlapping in longitudinal direction; overlaps are offset

Linear expansion during calibration: ~ 0.0%

Allowable diameter tolerance of the host pipes: DN ≤ 600: ± 5%* Carrier laminate thickness to EN ISO 11296-4 (07/2011)

- Contact

-

- Downloads

-

Data sheet

Brochure

Further language versions will follow.

Area of application

Berolina-LP-Liner: Area of application

Pressure pipes up to 3 bar operating pressure

- Circular profiles: ID 150 (6“) – ID 600 (24“)

Other sizes on request.

Advantages

Berolina-LP-Liner: Advantages

- Use in low-pressure range

- Seamless design

- Ready for installations up to 500 metres

- Can be stored for at least 5 months

- Fast curing

- Smooth surface

- Suitable for all standard pipe profiles

- Bridging small profile and cross-section changes

Technical data

Reinforcement material

Woven glass complex E-CR according to EN 14020-1, EN 14020-2 and EN 14020-3

Resins

Unsaturated polyester resins (UP resins)

- Type 1140 according to DIN 16946-2

- Group 3 according to DIN 18820-1

- Group 4 according to EN 13121-1

Technical data

Short-term ring stiffness (EN 1228)*: ≥ 10,000 N/mm²

Short-term modulus of elasticity in flexure (EN ISO 178)*: ≥ 8,700 N/mm²

Short-term flexural strength (EN ISO 178)*: ≥ 150 N/mm²

Reduction factor for long-term values (EN 761): A = 1.45

Long-term ring stiffness (EN 1228)*: ≥ 6,800 N/mm²

Long-term flexural strength (EN ISO 178)*: ≥ 105 N/mm²

Laminate design: Multi-layer, seamless and overlapping in longitudinal direction; overlaps are offset

Linear expansion during calibration: ~ 0.0%

Allowable diameter tolerance of the host pipes: DN ≤ 600: ± 5%

* Carrier laminate thickness to EN ISO 11296-4 (07/2011)

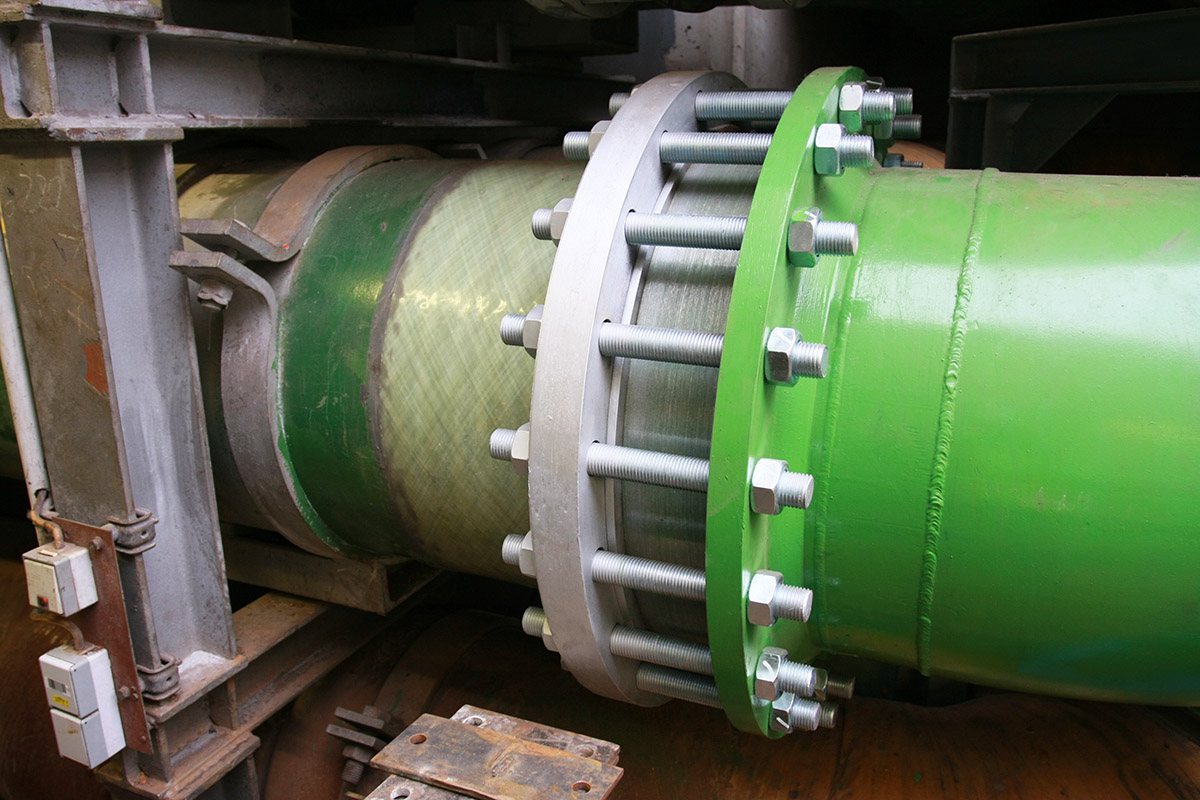

For an internal operating pressure up to 3 bar

The Berolina-LP-Liner (LP = Low Pressure) is used in wastewater pressure pipe rehabilitation. By using very resistant glass and the particularly favourable structural arrangement of the glass sheets, a maximum internal operating pressure of 3 bar is possible.

Reaching the target with low pressure

The standard Berolina-Liner was modified and used for the low-pressure range under the name Berolina-LP-Liner in order to rehabilitate pressure pipes too. This liner was installed for the first time in 2008, in the CHP plant in Reuter West in Berlin. The installation sequence differs from conventional rehabilitation methods due to the preparation and follow-up work. In wastewater pressure pipes, all sharp-edged deposits must be removed before the liner is pulled in. This is followed by pulling in a slip liner, the liner, calibration and UV light curing. The liner ends are joined onto the existing pipe by means of a flange joint. This method replaces the time-consuming replacement of pipe sections.