Other sizes on request.

Berolina-HF-Liner: Area of application

Gravity sewers

- Circular profiles: ID 400 (16“) – ID 1,600 (63“)

- Ovoid cross-sections: 350/525 mm (14“/21“) – 1,200/1,800 mm (47“/71“)

Berolina-HF-Liner with IES: Area of application

Gravity sewers

- Circular profiles: DN 400 (6“) – DN 600 (24“)

Berolina-HF-Liner: Advantages

- Higher mechanical characteristics compared to the Berolina-Liner

- Reduction of the structurally required wall thickness compared to the Berolina-Liner

- Seamless design

- Particular extensibility

- Ready for installations up to 500 meters or 1,000 meters (DN 200 [8“] to DN 300 [12“]))

- Can be stored for 6 months (VE liners) or 12 months (UP liners)

- Fast curing (particularly compared to felt liners)

- Smooth surface

- Fast curing (particularly compared to felt liners)

- Abrasion protection layer

- Bridging small profile and cross-section changes

- Resin types depending on requirements (polyester, vinyl ester, polystyrene-free)

- Quality management in accordance with EN ISO 9001:2015

Berolina-HF-Liner with IES: Additional advantages

Integrated Enhanced Security (available up to DN 600)

- Can be a substitute for smooth slip film

- Reducing installation time

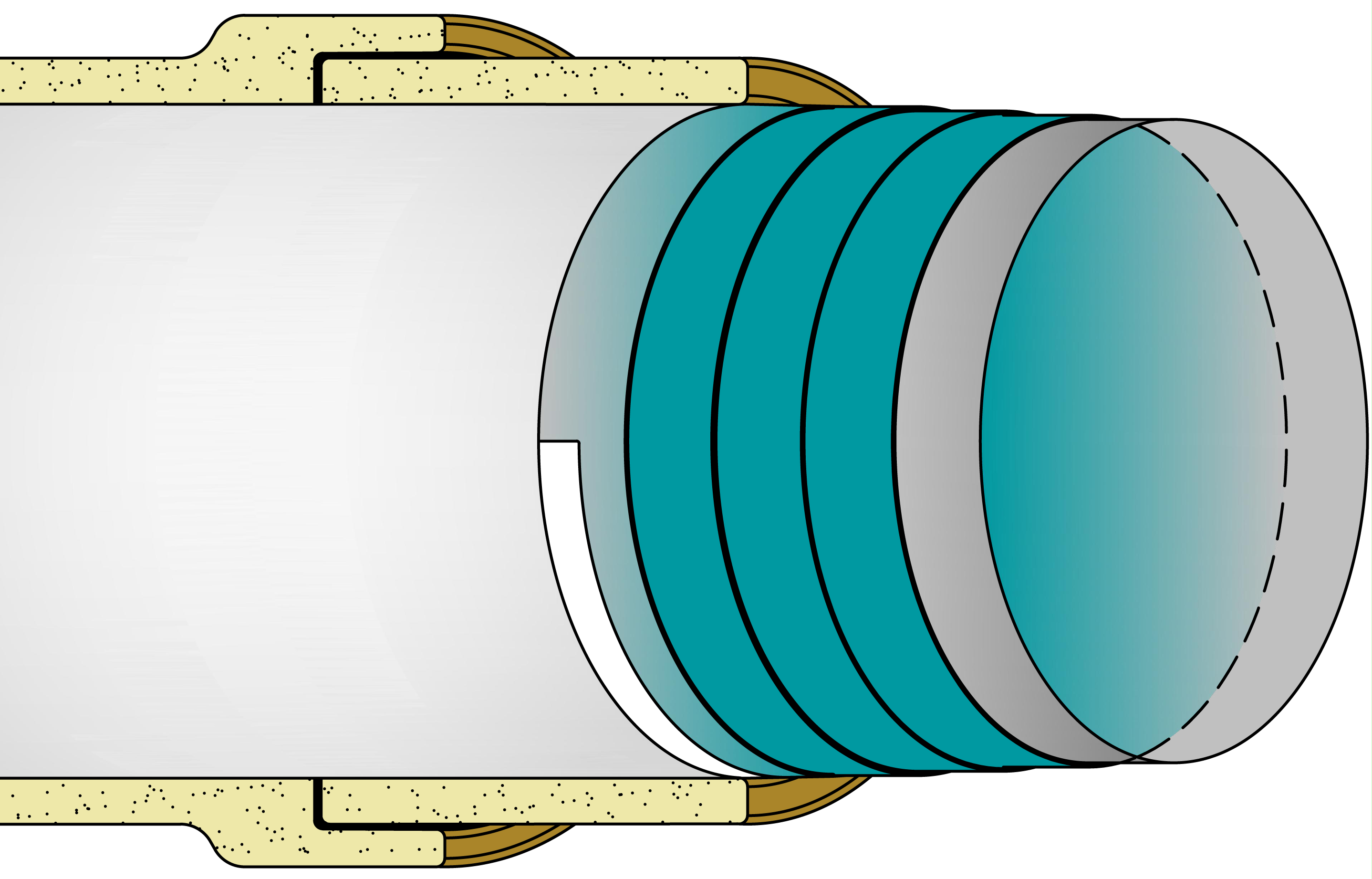

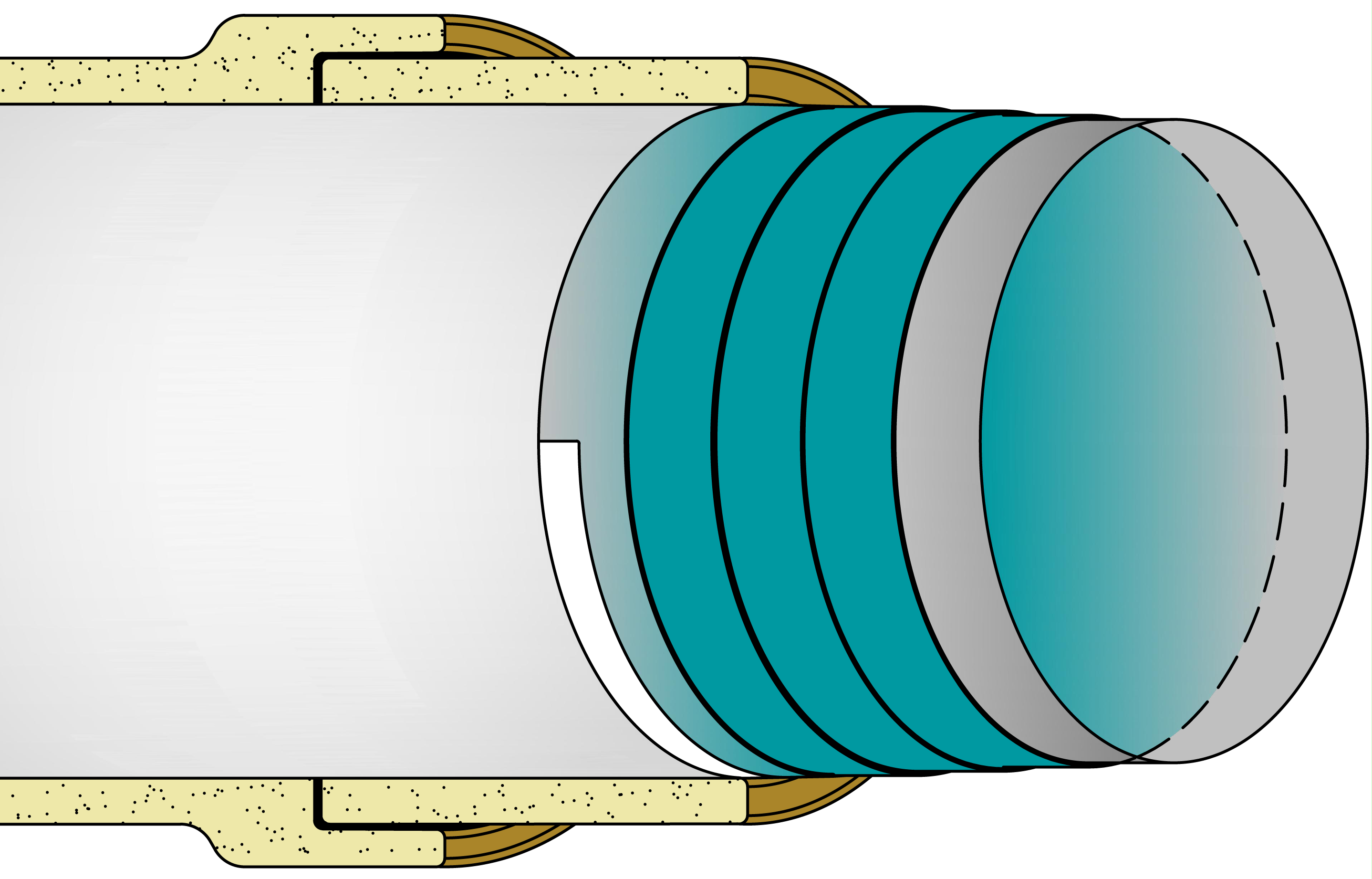

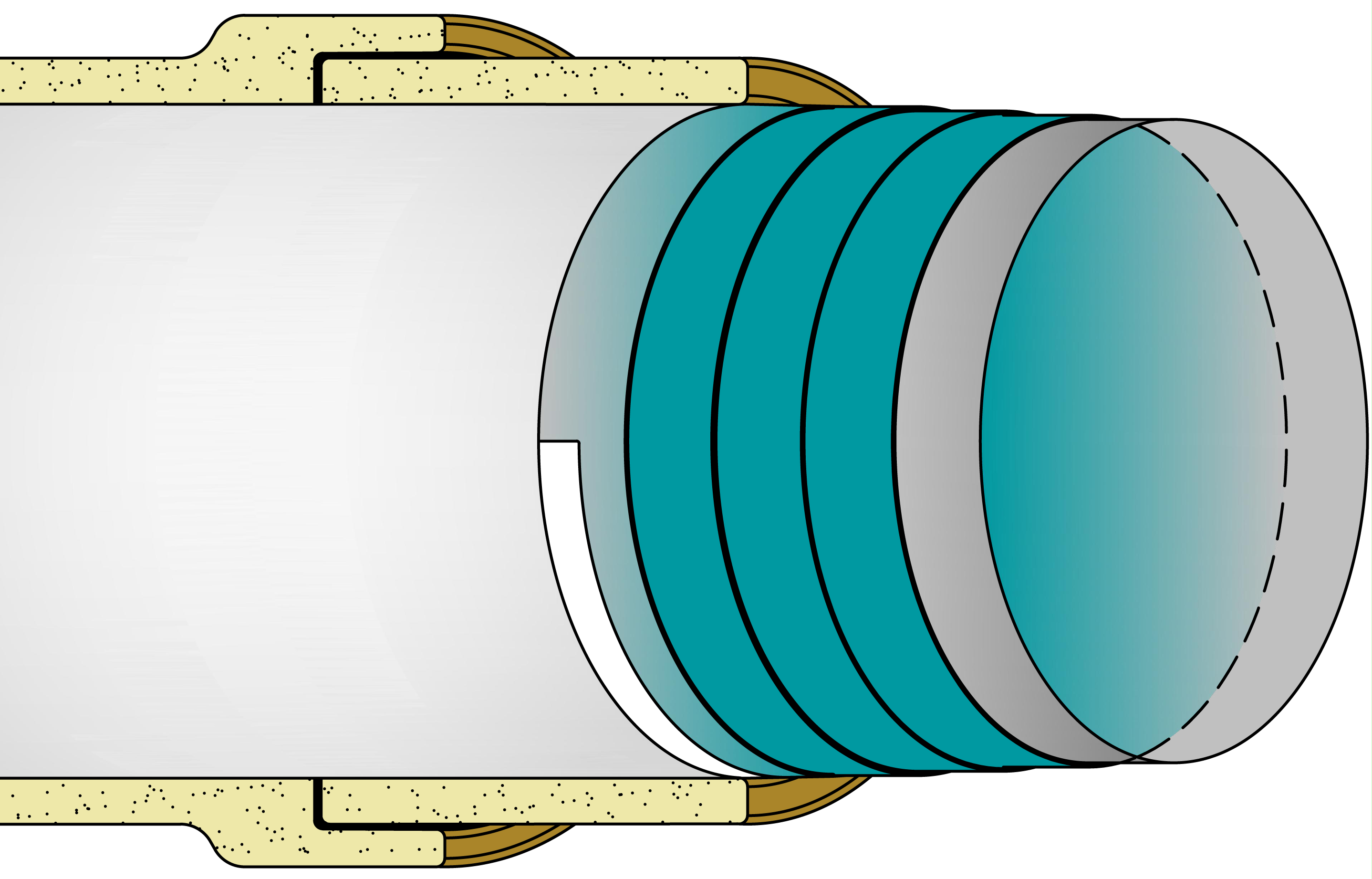

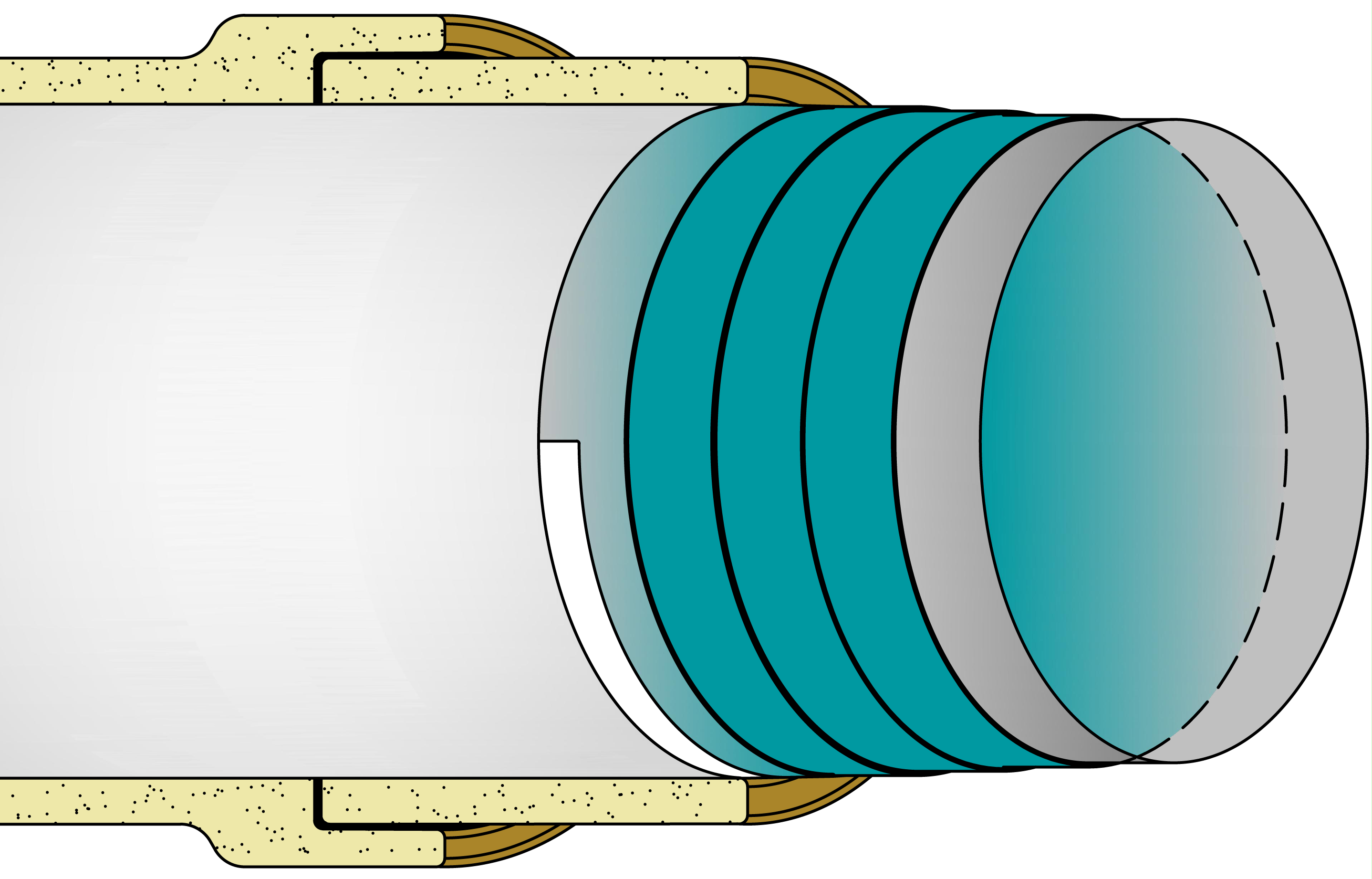

Structure of the Berolina-HF-Liner

- Inner film

- Abrasion protection layer

- Different glass layers

- Outer film with UV protective film

- Optional: Integrated Enhanced Security (IES)

- Host pipe

Reinforcement material

Non-crimp complex E-CR according to EN 14020-1, EN 14020-2 and EN 14020-3

Resins

Unsaturated polyester resins (UP resins)

- Type 1140 according to DIN 16946-2

- Group 3 according to DIN 18820-1

- Group 4 according to EN 13121-1

Vinyl ester resins (VE resins)

- Type 1310 according to DIN 16946-2

- Group 5 according to DIN 18820-1

- Group 7 B according to EN 13121-1

Styrene-free resin

Technical data

Approved for UP and VE resins

Density after curing (EN ISO 1183-2): 1.59g/cm³ (± 0.5 g/cm³)

Glass fibre content (EN ISO 1172 / by mass): 53% (± 8%)

Glass weight per unit area (per mm load-bearing wall thickness)*: 900g/m² (+150/-100g/m²)

Short-term ring stiffness (EN 1228)*: ≥ 17,000 N/mm²

Short-term modulus of elasticity (EN ISO 178)*: ≥ 17,000 N/mm²

Short-term flexural strength (EN ISO 178)*: ≥ 280 N/mm²

Reduction factor for long-term values (EN 761): A = 1.19

Long-term ring stiffness (EN 1228)*: ≥ 14,200 N/mm²

Long-term flexural strength (EN ISO 178)*: ≥ 235 N/mm²

Laminate design: Multi-layer, seemless and overlapping in longitudinal direction; overlaps are offset

Linear expansion during calibration: ~ 0.0%

Allowable diameter tolerances of the host pipes: DN ≤ 800: ± 5%; DN > 800: ± 2%

* Carrier laminate thickness to EN ISO 11296-4 (07/2011)

Data sheet

Brochure

Product approvals

Video: Berolina-Liner System – Virtual construction site

-

- Area of application

-

Berolina-HF-Liner: Area of application

Gravity sewers

- Circular profiles: ID 400 (16“) – ID 1,600 (63“)

- Ovoid cross-sections: 350/525 mm (14“/21“) – 1,200/1,800 mm (47“/71“)

Other sizes on request.

Berolina-HF-Liner with IES: Area of application

Gravity sewers

- Circular profiles: DN 400 (6“) – DN 600 (24“)

- Advantages

-

Berolina-HF-Liner: Advantages

- Higher mechanical characteristics compared to the Berolina-Liner

- Reduction of the structurally required wall thickness compared to the Berolina-Liner

- Seamless design

- Particular extensibility

- Ready for installations up to 500 meters or 1,000 meters (DN 200 [8“] to DN 300 [12“]))

- Can be stored for 6 months (VE liners) or 12 months (UP liners)

- Fast curing (particularly compared to felt liners)

- Smooth surface

- Fast curing (particularly compared to felt liners)

- Abrasion protection layer

- Bridging small profile and cross-section changes

- Resin types depending on requirements (polyester, vinyl ester, polystyrene-free)

- Quality management in accordance with EN ISO 9001:2015

Berolina-HF-Liner with IES: Additional advantages

Integrated Enhanced Security (available up to DN 600)

- Can be a substitute for smooth slip film

- Reducing installation time

- Structure

-

Structure of the Berolina-HF-Liner

- Inner film

- Abrasion protection layer

- Different glass layers

- Outer film with UV protective film

- Optional: Integrated Enhanced Security (IES)

- Host pipe

- Technical data

-

Reinforcement material

Non-crimp complex E-CR according to EN 14020-1, EN 14020-2 and EN 14020-3

Resins

Unsaturated polyester resins (UP resins)

- Type 1140 according to DIN 16946-2

- Group 3 according to DIN 18820-1

- Group 4 according to EN 13121-1

Vinyl ester resins (VE resins)

- Type 1310 according to DIN 16946-2

- Group 5 according to DIN 18820-1

- Group 7 B according to EN 13121-1

Styrene-free resin

Technical data

Approved for UP and VE resins

Density after curing (EN ISO 1183-2): 1.59g/cm³ (± 0.5 g/cm³)

Glass fibre content (EN ISO 1172 / by mass): 53% (± 8%)

Glass weight per unit area (per mm load-bearing wall thickness)*: 900g/m² (+150/-100g/m²)Short-term ring stiffness (EN 1228)*: ≥ 17,000 N/mm²

Short-term modulus of elasticity (EN ISO 178)*: ≥ 17,000 N/mm²

Short-term flexural strength (EN ISO 178)*: ≥ 280 N/mm²Reduction factor for long-term values (EN 761): A = 1.19

Long-term ring stiffness (EN 1228)*: ≥ 14,200 N/mm²

Long-term flexural strength (EN ISO 178)*: ≥ 235 N/mm²Laminate design: Multi-layer, seemless and overlapping in longitudinal direction; overlaps are offset

Linear expansion during calibration: ~ 0.0%

Allowable diameter tolerances of the host pipes: DN ≤ 800: ± 5%; DN > 800: ± 2%* Carrier laminate thickness to EN ISO 11296-4 (07/2011)

- Contact

-

- Downloads

-

Data sheet

Brochure

Product approvals

- Virtual construction site

-

Video: Berolina-Liner System – Virtual construction site

Area of application

Berolina-HF-Liner: Area of application

Gravity sewers

- Circular profiles: ID 400 (16“) – ID 1,600 (63“)

- Ovoid cross-sections: 350/525 mm (14“/21“) – 1,200/1,800 mm (47“/71“)

Other sizes on request.

Berolina-HF-Liner with IES: Area of application

Gravity sewers

- Circular profiles: DN 400 (6“) – DN 600 (24“)

Advantages

Berolina-HF-Liner: Advantages

- Higher mechanical characteristics compared to the Berolina-Liner

- Reduction of the structurally required wall thickness compared to the Berolina-Liner

- Seamless design

- Particular extensibility

- Ready for installations up to 500 meters or 1,000 meters (DN 200 [8“] to DN 300 [12“]))

- Can be stored for 6 months (VE liners) or 12 months (UP liners)

- Fast curing (particularly compared to felt liners)

- Smooth surface

- Fast curing (particularly compared to felt liners)

- Abrasion protection layer

- Bridging small profile and cross-section changes

- Resin types depending on requirements (polyester, vinyl ester, polystyrene-free)

- Quality management in accordance with EN ISO 9001:2015

Berolina-HF-Liner with IES: Additional advantages

Integrated Enhanced Security (available up to DN 600)

- Can be a substitute for smooth slip film

- Reducing installation time

Structure

Structure of the Berolina-HF-Liner

- Inner film

- Abrasion protection layer

- Different glass layers

- Outer film with UV protective film

- Optional: Integrated Enhanced Security (IES)

- Host pipe

Technical data

Reinforcement material

Non-crimp complex E-CR according to EN 14020-1, EN 14020-2 and EN 14020-3

Resins

Ungesättigte Polyesterharze (UP-Harze)

- Typ 1140 gemäß DIN 16946-2

- Gruppe 3 gemäß DIN 18820-1

- Gruppe 4 gemäß EN 13121-1

Vinylesterharze (VE-Harze)

- Typ 1310 gemäß DIN 16946-2

- Gruppe 5 gemäß DIN 18820-1

- Gruppe 7 B gemäß EN 13121-1

Styrolfreies Harz

Technical data

Approved for UP and VE resins

Density after curing (EN ISO 1183-2): 1.59g/cm³ (± 0.5 g/cm³)

Glass fibre content (EN ISO 1172 / by mass): 53% (± 8%)

Glass weight per unit area (per mm load-bearing wall thickness)*: 900g/m² (+150/-100g/m²)

Short-term ring stiffness (EN 1228)*: ≥ 17,000 N/mm²

Short-term modulus of elasticity (EN ISO 178)*: ≥ 17,000 N/mm²

Short-term flexural strength (EN ISO 178)*: ≥ 280 N/mm²

Reduction factor for long-term values (EN 761): A = 1.19

Long-term ring stiffness (EN 1228)*: ≥ 14,200 N/mm²

Long-term flexural strength (EN ISO 178)*: ≥ 235 N/mm²

Laminate design: Multi-layer, seemless and overlapping in longitudinal direction; overlaps are offset

Linear expansion during calibration: ~ 0.0%

Allowable diameter tolerances of the host pipes: DN ≤ 800: ± 5%; DN > 800: ± 2%

* Carrier laminate thickness to EN ISO 11296-4 (07/2011)

Downloads

Data sheet

Brochure

Product approvals

- WRc PT405/0417 (UP and VE resins)

- City of Los Angeles, CA, USA (UP and VE resins)

- DIBt Z-42.3-336 (UP and VE resins)

- CSTB 17.2/15-303_V1 (UP resins)

Faster curing and easier handling

Due to the special construction of the glass sheets and higher glass content, the Berolina-HF-Liner achieves higher mechanical characteristics resulting in a reduction of the structurally required wall thickness compared to the normal Berolina-Liner. The resulting lower weight allows easier handling.

The Berolina-HF-Liner is also available with Integrated Enhanced Security (IES) – a smooth slip film is no longer necessary for the pulling in with the result that installation time can be reduced by up to 60 minutes.

Der Aufbau des Berolina-HF-Liners

12 steps to complete pipe rehabilitation

1. Secure the construction site

2. Thoroughly clean the pipe to be rehabilitated

3. CCTV pipe inspection beforehand

4. Pull in the smooth slip film (not necessary for liners with IES)

5. Pull in the liner by means of a winch

6. Close off the pipe ends with end-cans

7. Pull in the UV light source

8. Inflate the liner against the pipe wall with compressed air

9. Cure the liner by means of a light source with a defined speed

10. Open the pipe ends (removal of the end-cans and flush cutting off)

11. Remove of the inner film

12. Cut open the easy to find inlets