GRP Pipe Coating: Advantages

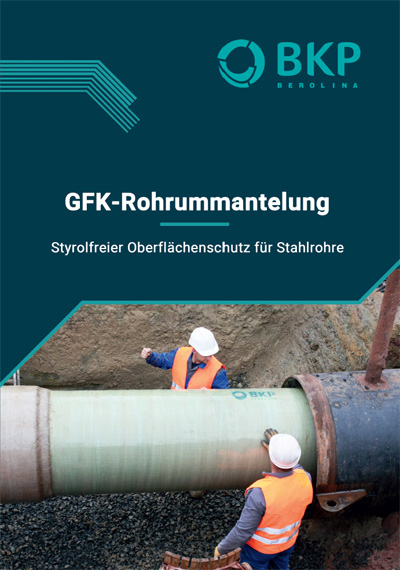

Glass fibre reinforced plastic (GRP) is an extremely resilient material, which BKP applies on the PE coated pipes as casing protection. This additional protective coat is used in particular for the pipe jacking and horizontal drilling method (HDD). The GRP coating applied in the factory is convincingly effective due to the use of polystyrene-free resins and the fast curing by means of controlled UV light.

- GRP protective reinforcement

- ID 100 – ID 1,400

- Also available with GRP skids

- High impact and abrasion resistance

- Maximum protection from mechanical damage on pulling in the pipe

- Chemical and light resistant

Material

The around five millimetre thick GRP pipe coating of the BKP Berolina is made of light-curing resins and is applied on the PE sheathed pipe. Combined with the high-strength glass fibres, the corrosion protection system protects against mechanical damage while the pipe is pulled in.

Mechanical characteristics

Thickness of the Berolina protection system: >= 5 mm

Dielectric strength: >= 25 000 V

Laminate weight per unit area: > 9400 g/m²

Laminate density: > 1700 kg/m³

Total glass fraction: > 60 %

Total glass weight per unit area: > 5600 g/m²

Glass distribution: > 3 : 1 tan:ax

Shear strength GRP/PE (according to GW340): ≥ 100 N/cm²

Hardness (Barcol): > 45 scale division

Polystyrene emissions: 0 ppm

Volume shrinkage (laminate): < 1 %

Brochure

Major projects to date

Pipe jacking and horizontal drilling method (HDD)

- STEGAL (Sachsen-Thüringen-Erdgas-Leitung)

- NEL (Nordeuropäische Erdgasleitung)

- OPAL (Ostsee-Pipeline-Anbindungsleitung)

- JAGAL (Jamal-Gas-Anbindungs-Leitung)

- WEDAL (Westdeutschland-Anbindungsleitung)

Technical data

Material

The around five millimetre thick GRP pipe coating of the BKP Berolina is made of light-curing resins and is applied on the PE sheathed pipe. Combined with the high-strength glass fibres, the corrosion protection system protects against mechanical damage while the pipe is pulled in.

Mechanical characteristics

Thickness of the Berolina protection system: >= 5 mm

Dielectric strength: >= 25 000 V

Laminate weight per unit area: > 9400 g/m²

Laminate density: > 1700 kg/m³

Total glass fraction: > 60 %

Total glass weight per unit area: > 5600 g/m²

Glass distribution: > 3 : 1 tan:ax

Hardness (Barcol): > 45 scale division

Polystyrene emissions: 0 ppm

Volume shrinkage (laminate): < 1 %

References

Previous major projects

Pipe jacking and horizontal drilling method (HDD)

- STEGAL (Sachsen-Thüringen-Erdgas-Leitung)

- NEL (Nordeuropäische Erdgasleitung)

- OPAL (Ostsee-Pipeline-Anbindungsleitung)

- JAGAL (Jamal-Gas-Anbindungs-Leitung)

- WEDAL (Westdeutschland-Anbindungsleitung)

The protective reinforcement made of glass fibre reinforced plastic

Due to the enormous wear resistance, which conventional polyethylene/polypropylene (PE/PP) coatings do not have, damage is avoided when pulling in. Follow-up costs due to subsequent report, or the replacement of a damaged pipe are not necessary. The GRP coating applied mechanically in the factory is subjected to the strictest quality requirements.

Maximum mechanical abrasive strength for trenchless pipe jacking

The GRP pipe coating is applied on the PE coated pipe using a special method. This is a glass fibre reinforced plastic, which is cured in the factory by means of UV light.

GRP pipe coating: A success story

BKP developed the glass fibre reinforced pipe coating in the mid-1990s, working with a renowned gas grid operator. Since then the objective has been to protect the corrosion protection applied to the pipe by means of a high-strength GRP coating. The extremely heavy-duty coating made of glass fibres and polystyrene-free resin ensures maximum mechanical abrasion resistance for trenchless pipe installation (pulling in of pipes). The high-strength material is cured in a controlled way by UV light without the use of curing agents (hardeners) and accelerators.

The protective reinforcement made of glass fibre reinforced plastic

Due to the enormous wear resistance, which conventional polyethylene/polypropylene (PE/PP) coatings do not have, damage is avoided when pulling in. Follow-up costs due to subsequent report, or the replacement of a damaged pipe are not necessary. The GRP coating applied mechanically in the factory is subjected to the strictest quality requirements.

Maximum mechanical abrasive strength for trenchless pipe jacking

The GRP pipe coating is applied on the PE coated pipe using a special method. This is a glass fibre reinforced plastic, which is cured in the factory by means of UV light.

GRP pipe casing: A success story

BKP developed the glass fibre reinforced pipe coating in the mid-1990s, working with a renowned gas grid operator. Since then the objective has been to protect the corrosion protection applied to the pipe by means of a high-strength GRP coating. The extremely heavy-duty coating made of glass fibres and polystyrene-free resin ensures maximum mechanical abrasion resistance for trenchless pipe installation (pulling in of pipes). The high-strength material is cured in a controlled way by UV light without the use of curing agents (hardeners) and accelerators.