Other sizes and cross-sections are possible on request.

Berolina-Liner: Area of application

Gravity sewers

- Circular profiles: DN 150 (6“) – 950 (37“)

- Ovoid cross-sections: 200/300 mm (8“/12“) – 700/1.050 mm (28“/41“)

Berolina-Liner with IES: Area of application

Gravity sewers

- Circular profiles: DN 150 (6“) – DN 600 (24“)

Berolina-Liner: Advantages

- Seamless construction

- Particular extensibility

- Ready for installations up to 500 meters (DN 200 – DN 300 up to 1,000 meters)

- Can be stored for 6 months (VE liners) or 12 months (UP liners)

- Fast curing

- Smooth surface

- Suitable for all standard pipe profiles

- Abrasion protection layer

- Bridging small profile and cross-section changes

- Resin types depending on the requirement (polyester resin, vinyl ester resin, polystyrene-free resin)

- Quality management in accordance with EN ISO 9001:2015

Berolina-Liner with IES: Additional advantages

Integrated Enhanced Security (available up to DN 600)

- Can be a substitute for smooth slip film

- Reducing installation time

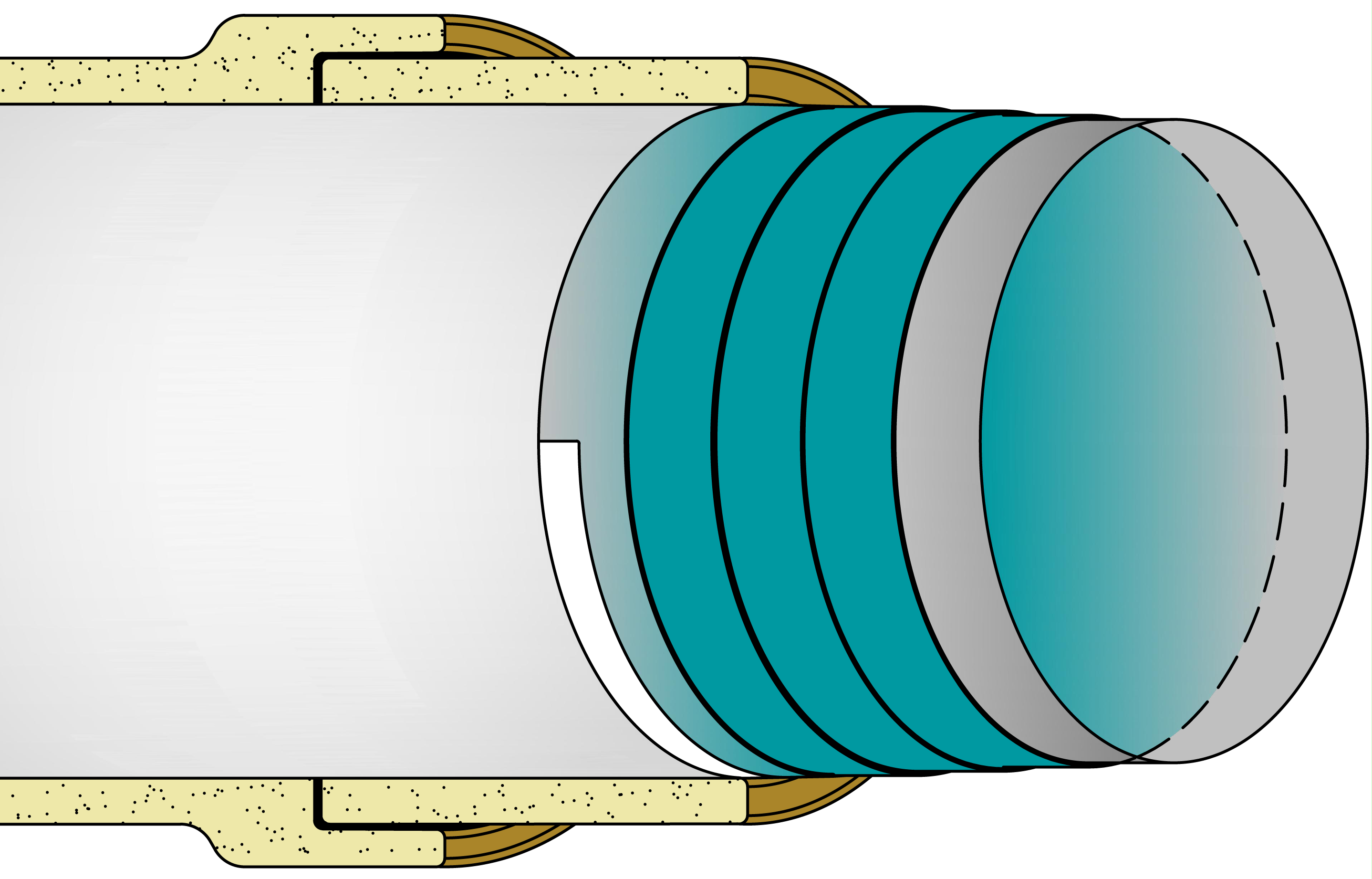

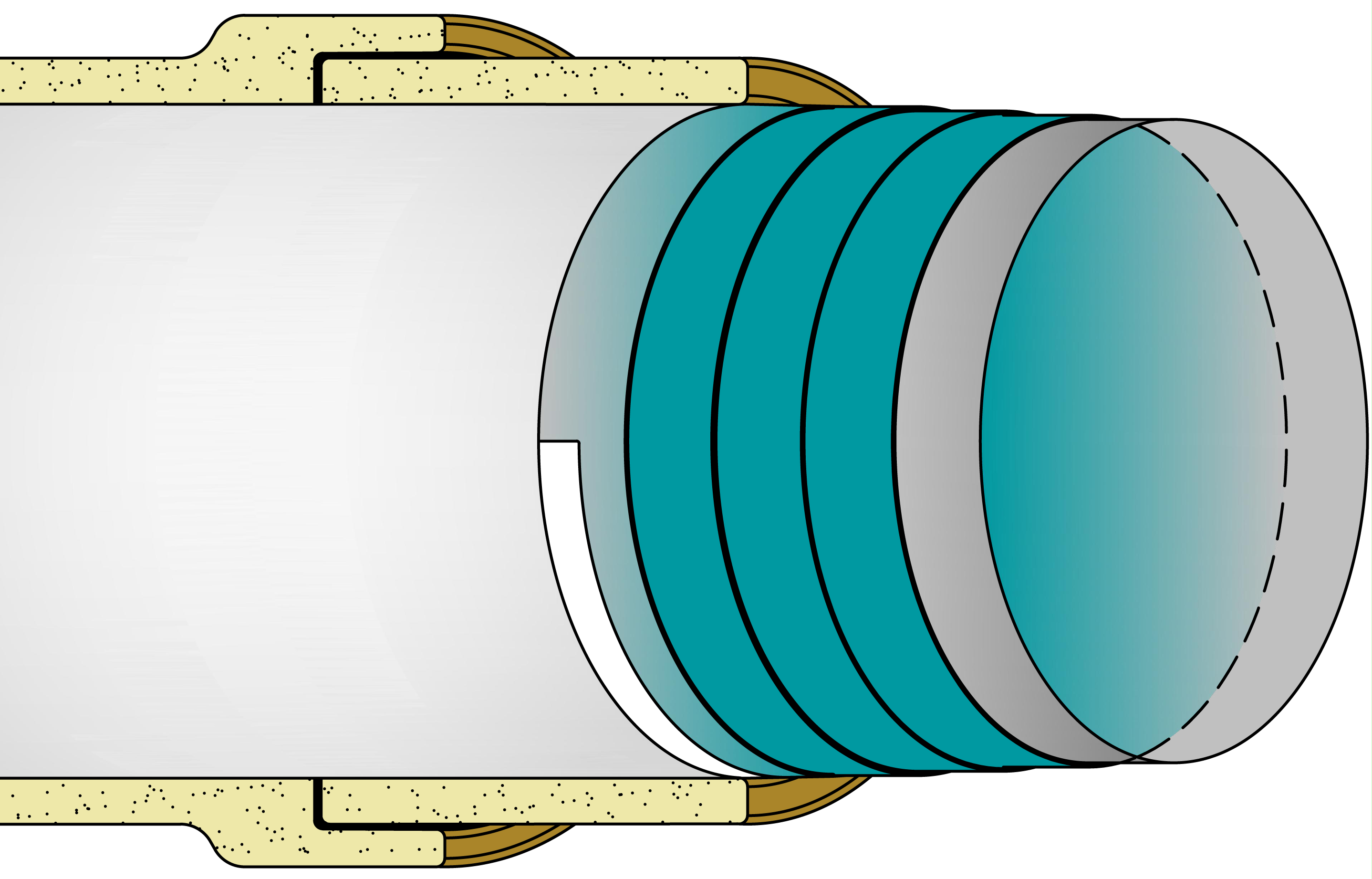

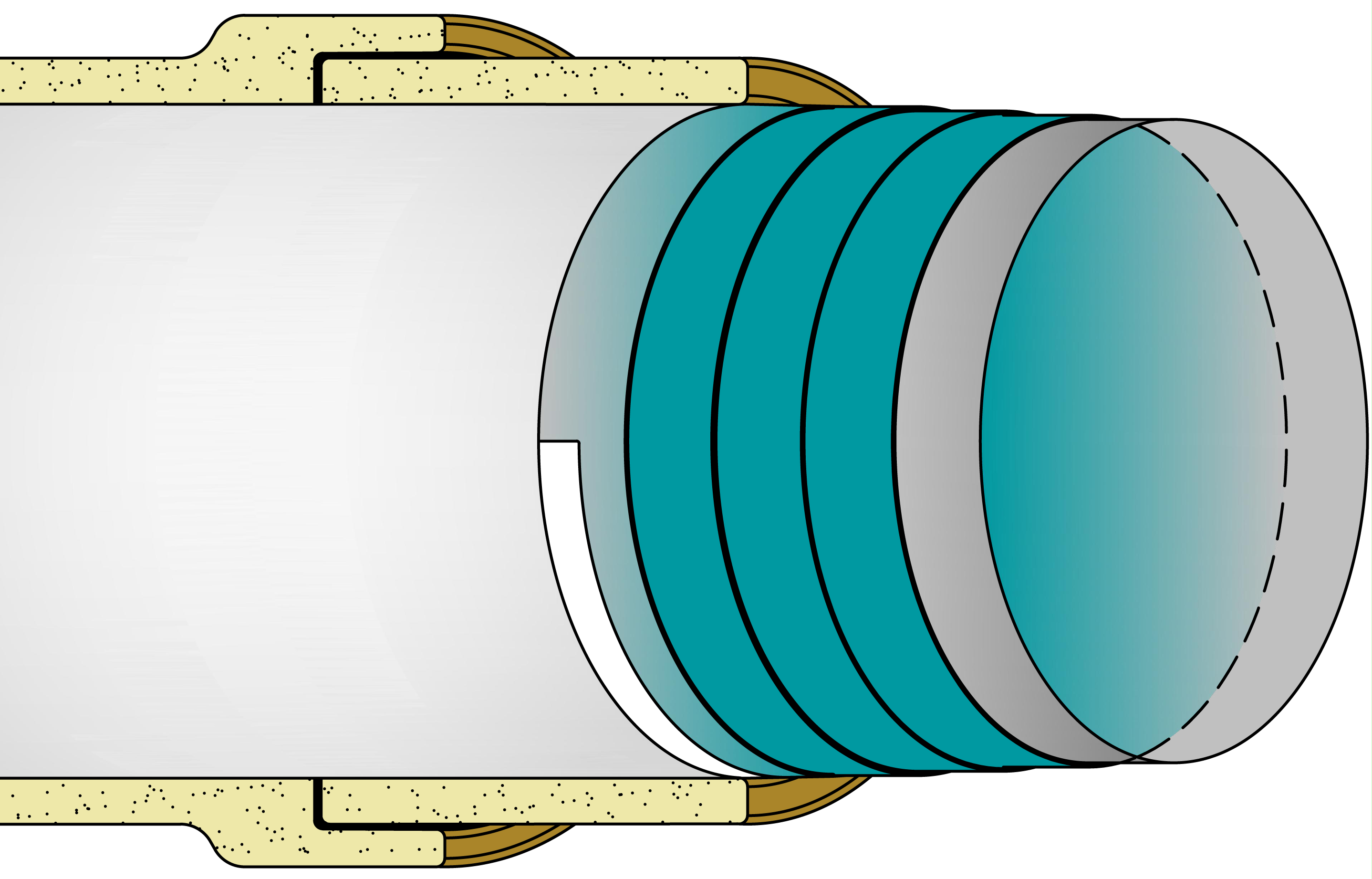

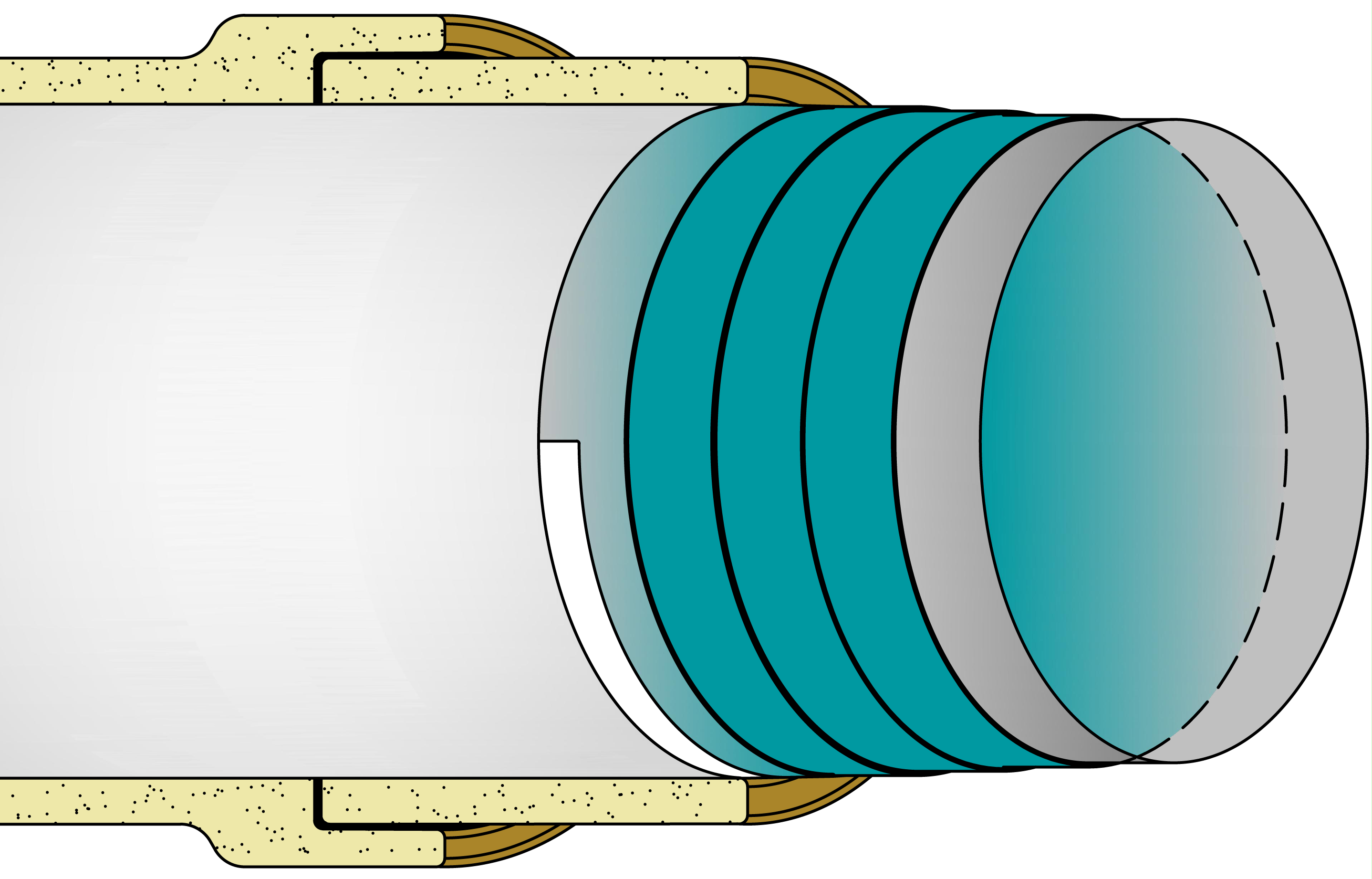

Structure of the Berolina-Liner

- Inner film

- Abrasion protection layer

- Different glass layers

- Outer film with UV protective film

- Optional: Integrated Enhanced Security (IES)

- Host pipe

Reinforcement material

Woven glass complex E-CR according to EN 14020-1, EN 14020-2 und EN 14020-3

Resins

Unsaturated polyester resins (UP resins)

- Type 1140 according to DIN 16946-2

- Group 3 according to DIN 18820-1

- Group 4 according to EN 13121-1

Vinyl ester resins (VE resins)

- Type 1310 according to DIN 16946-2

- Group 5 according to DIN 18820-1

- Group 7 B according to EN 13121-1

Polystyrene-free resins

Technical data

Approved for UP and VE resins

Density after curing (EN ISO 1183-2): 1.5g/cm³ (± 0.5 g/cm³)

Glass fibre content (EN ISO 1172 / by mass): 46% (± 8%)

Glass weight per unit area (per mm load-bearing wall thickness)*: 650 g/m² (+150/-100g/m²)

Short-term ring stiffness (EN 1228)*: ≥ 10,000 N/mm²

Short-term modulus of elasticity in flexure (EN ISO 178)*: ≥ 8,700 N/mm²

Short-term flexural strength (EN ISO 178)*: ≥ 150 N/mm²

Reduction factor for long-term values (EN 761): A = 1.45

Long-term ring stiffness (EN 1228)*: ≥ 6,800 N/mm²

Long-term flexural strength (EN ISO 178)*: ≥ 105 N/mm²

Laminate design: Multi-layer, seamless and overlapping in longitudinal direction; overlaps are offset

Linear expansion during calibration: ~ 0.0%

Allowable diameter tolerances of the host pipes: DN ≤ 800: ± 5%; DN > 800: ± 2%

* Carrier laminate thickness to EN ISO 11296-4 (07/2011)

Video: Berolina-Liner System – Virtual construction site

-

- Area of application

-

Berolina-Liner: Area of application

Gravity sewers

- Circular profiles: DN 150 (6“) – 950 (37“)

- Ovoid cross-sections: 200/300 mm (8“/12“) – 700/1.050 mm (28“/41“)

Other sizes and cross-sections are possible on request.

Berolina-Liner with IES: Area of application

Gravity sewers

- Circular profiles: DN 150 (6“) – DN 600 (24“)

- Advantages

-

Berolina-Liner: Advantages

- Seamless construction

- Particular extensibility

- Ready for installations up to 500 meters (DN 200 – DN 300 up to 1,000 meters)

- Can be stored for 6 months (VE liners) or 12 months (UP liners)

- Fast curing

- Smooth surface

- Suitable for all standard pipe profiles

- Abrasion protection layer

- Bridging small profile and cross-section changes

- Resin types depending on the requirement (polyester resin, vinyl ester resin, polystyrene-free resin)

- Quality management in accordance with EN ISO 9001:2015

Berolina-Liner with IES: Additional advantages

Integrated Enhanced Security (available up to DN 600)

- Can be a substitute for smooth slip film

- Reducing installation time

- Structure

-

Structure of the Berolina-Liner

- Inner film

- Abrasion protection layer

- Different glass layers

- Outer film with UV protective film

- Optional: Integrated Enhanced Security (IES)

- Host pipe

- Technical data

-

Reinforcement material

Woven glass complex E-CR according to EN 14020-1, EN 14020-2 und EN 14020-3

Resins

Unsaturated polyester resins (UP resins)

- Type 1140 according to DIN 16946-2

- Group 3 according to DIN 18820-1

- Group 4 according to EN 13121-1

Vinyl ester resins (VE resins)

- Type 1310 according to DIN 16946-2

- Group 5 according to DIN 18820-1

- Group 7 B according to EN 13121-1

Polystyrene-free resins

Technical data

Approved for UP and VE resins

Density after curing (EN ISO 1183-2): 1.5g/cm³ (± 0.5 g/cm³)

Glass fibre content (EN ISO 1172 / by mass): 46% (± 8%)

Glass weight per unit area (per mm load-bearing wall thickness)*: 650 g/m² (+150/-100g/m²)Short-term ring stiffness (EN 1228)*: ≥ 10,000 N/mm²

Short-term modulus of elasticity in flexure (EN ISO 178)*: ≥ 8,700 N/mm²

Short-term flexural strength (EN ISO 178)*: ≥ 150 N/mm²Reduction factor for long-term values (EN 761): A = 1.45

Long-term ring stiffness (EN 1228)*: ≥ 6,800 N/mm²

Long-term flexural strength (EN ISO 178)*: ≥ 105 N/mm²Laminate design: Multi-layer, seamless and overlapping in longitudinal direction; overlaps are offset

Linear expansion during calibration: ~ 0.0%

Allowable diameter tolerances of the host pipes: DN ≤ 800: ± 5%; DN > 800: ± 2%* Carrier laminate thickness to EN ISO 11296-4 (07/2011)

- Contact

-

- Downloads

- Virtual construction site

-

Video: Berolina-Liner System – Virtual construction site

Area of application

Berolina-Liner: Area of application

Gravity sewers

- Circular profiles: DN 150 (6“) – 950 (37“)

- Ovoid cross-sections: 200/300 mm (8“/12“) – 700/1.050 mm (28“/41“)

Other sizes and cross-sections are possible on request.

Berolina-Liner with IES: Area of application

Gravity sewers

- Circular profiles: DN 150 (6“) – DN 600 (24“)

Advantages

Berolina-Liner: Advantages

- Seamless construction

- Particular extensibility

- Ready for installations up to 500 meters (DN 200 – DN 300 up to 1,000 meters)

- Can be stored for 6 months (VE liners) or 12 months (UP liners)

- Fast curing

- Smooth surface

- Suitable for all standard pipe profiles

- Abrasion protection layer

- Bridging small profile and cross-section changes

- Resin types depending on the requirement (polyester resin, vinyl ester resin, polystyrene-free resin)

- Quality management in accordance with EN ISO 9001:2015

Berolina-Liner with IES: Additional advantages

Integrated Enhanced Security (available up to DN 600)

- Can be a substitute for smooth slip film

- Reducing installation time

Structure

Structure of the Berolina-Liner

- Inner film

- Abrasion protection layer

- Different glass layers

- Outer film with UV protective film

- Optional: Integrated Enhanced Security (IES)

- Host pipe

Technical data

Reinforcement material

Woven glass complex E-CR according to EN 14020-1, EN 14020-2 und EN 14020-3

Resins

Unsaturated polyester resins (UP resins)

- Type 1140 according to DIN 16946-2

- Group 3 according to DIN 18820-1

- Group 4 according to EN 13121-1

Vinyl ester resins (VE resins)

- Type 1310 according to DIN 16946-2

- Group 5 according to DIN 18820-1

- Group 7 B according to EN 13121-1

Polystyrene-free resins

Technical data

Approved for UP and VE resins

Density after curing (EN ISO 1183-2): 1.5g/cm³ (± 0.5 g/cm³)

Glass fibre content (EN ISO 1172 / by mass): 46% (± 8%)

Glass weight per unit area (per mm load-bearing wall thickness)*: 650 g/m² (+150/-100g/m²)

Short-term ring stiffness (EN 1228)*: ≥ 10,000 N/mm²

Short-term modulus of elasticity in flexure (EN ISO 178)*: ≥ 8,700 N/mm²

Short-term flexural strength (EN ISO 178)*: ≥ 150 N/mm²

Reduction factor for long-term values (EN 761): A = 1.45

Long-term ring stiffness (EN 1228)*: ≥ 6,800 N/mm²

Long-term flexural strength (EN ISO 178)*: ≥ 105 N/mm²

Laminate design: Multi-layer, seamless and overlapping in longitudinal direction; overlaps are offset

Linear expansion during calibration: ~ 0.0%

Allowable diameter tolerances of the host pipes: DN ≤ 800: ± 5%; DN > 800: ± 2%

* Carrier laminate thickness to EN ISO 11296-4 (07/2011)

Fast, effective and trenchless

The Berolina-Liner System is a cost-effective and efficient method for sewer pipe rehabilitation. Time-consuming excavation work can be avoided – the disruption to infrastructure is minor and short-term. Compared with other methods energy consumption is reduced significantly thanks to optimised production, transportation and installation conditions. Since 1997, BKP has successfully produced UV light-curing and glass fibre reinforced tube liners.

Different liner types are available to meet most requirements for sewers in need of rehabilitation:

High mechanical characteristics enables low cross-section loss

The Berolina-Liner provides optimum benefits for trenchless rehabilitation of wastewater sewers, for every user. The factory resin-impregnated liner is pulled into the existing pipe to be rehabilitated, pressed against the old pipe by with compressed air and cured using UV light. The sewer pipe is thus sealed from the inside and its structural load-bearing capacity is restored. Depending on the requirements, the glass fibre layers of the liner are impregnated with high-quality unsaturated polyester or vinyl ester resins. They are arranged in such a way so as to overlap and offset with each other between two water and polystyrene-tight film tubes. The glass fibre orientation is also matched to the existing pull-in forces of the liner. Thanks to the glass fibre reinforcement, small wall-thicknesses are sufficient to strengthen the old pipe permanently. The loss in cross-section of a rehabilitated pipe is thus reduced to a minimum and the load-bearing capacity of the pipe system is simultaneously improved. Curing speeds vary depending on the diameter and wall thickness of the Berolina-Liner.

Highly adaptable due to particular flexibility

The seamless and undersized initial construction provides the Berolina-Liner with a high degree of variability and in particular extensibility or elasticity, which enables the liner to lie flush with an old pipe made of any material. If planned and preassembled appropriately, it adapts itself to any profile; small cross-sections or profile changeovers up to a maximum of eight percent of the nominal diameter are generally not a problem. The structural glass orientation in the circumferential direction optimises the flow of force without limiting the extension. All BKP Berolina liners are produced with a protective inner film included, which is particularly resistant and is easy to remove after installation. The UV-tight outer film bonded onto the liner is also standardised. At the request of the customer, the tube liners can also be offered with optional Integrated Enhanced Security (IES), as a substitute for the conventional smooth slip film, for less damaged sewers. In addition, Berolina-Liners have an abrasion protection layer on the inside.

The structure of the Berolina-Liner

Berolina-Liner unique

Berolina-Liner unique

12 steps to complete pipe rehabilitation

1. Secure the construction site

2. Thoroughly clean the pipe to be rehabilitated

3. CCTV pipe inspection beforehand

4. Pull in the smooth slip film (not necessary for liners with IES)

5. Pull in the liner by means of a winch

6. Close off the pipe ends with end-cans

7. Pull in the UV light source

8. Inflate the liner against the pipe wall with compressed air

9. Cure the liner by means of a light source with a defined speed

10. Open the pipe ends (removal of the end-cans and flush cutting off)

11. Remove of the inner film

12. Cut open the easy to find inlets